Innovative Downhole Completion Tools

We work alongside our clients around the world to solve their well completion challenges, linking engineered design with manufacturing and operations. This provides quick turnaround and flexible customized solutions that fit client specific applications.

We ensure every design meets stringent QA/QC specifications and industry requirements before launching the tool, providing our clients with leading tool reliability and downhole performance.

Multistage Systems

StrataJet Multistage Coil Frac Sleeve provides full ID and 360° reservoir access with unlimited stages

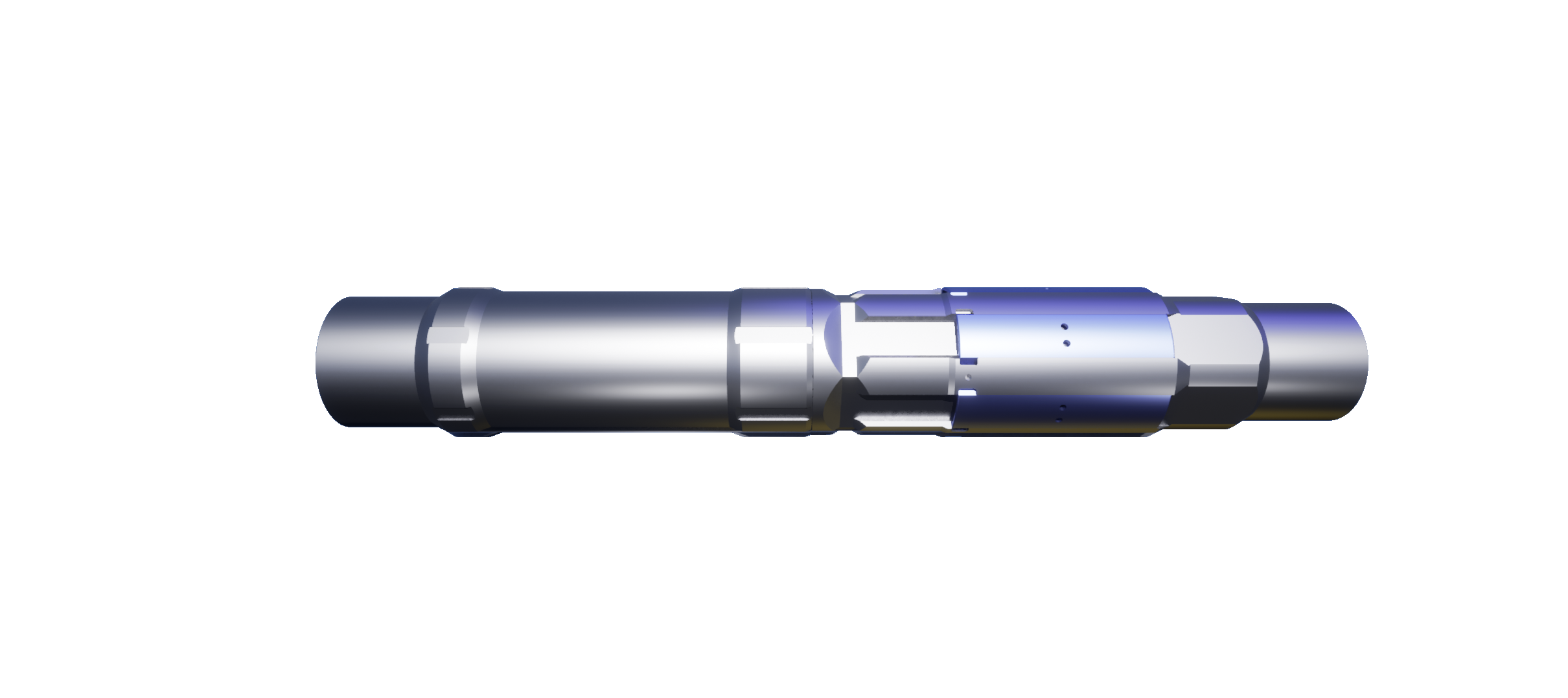

Raptor OC (Open Close) coil sleeves for complete stimulation and production control

Interra’s RPG™(Replace Perforating Guns) system is a field-proven, unlimited stage system designed for both single and multipoint entry.

Toe Initiation

AccuJet Toe Initiation Sleeve eliminates the need for perforating to initiate reservoir communication

Howitzer Pressure Testable Toe Sleeve enables full casing integrity test then automatically opens at a lower pressure

XacToe Initiation Sleeve provides consistent and reliable opening pressure accuracy

Raptor Closeable Toe Initiation Sleeve isolates the entire wellbore post-frac without the need to run plugs

The Slimhole Toe Initiation Sub provides differential pressure activation with reduced OD while maximizing ID

Coiled Tubing Tools

AccuStim coiled tubing straddle packer reliably isolates new or existing perforation intervals for hydraulic stimulation

Raptor annular frac packer Velocity shifting tool enable reliable activation and stimulation of Raptor OC shift-frac-close coil sleeves

AccuShift thermal shifting tool provides simple and reliable functioning of thermal valves in SAGD wells

SAGD Completion Tools

AccuSteam Injection Valve enhances operators' ability to maximize steam conformance in SAGD injector wells

AccuFlow Production Valve provides inflow control with open and close capability to optimize SAGD production

The Thermal Overshot Completion Tool facilitates efficient recovery of parted tubulars in high-temperature SAGD environments

Specialty Tools

Black Phantom Floatation Sub ensures casing installs to TD in extended reach wells

Interra Energy client Success Stories

Interra Energy Case Studies

Pre-perforated completions are employed in numerous formations in Saskatchewan and Alberta where they provide advantages over conventional plug-and-perf stimulation. Instead of multiple trips in and out of the wellbore to set plugs for stage-to-stage isolation, pre-perforated wells are stimulated using coiled tubing straddle tools, which can treat the entire wellbore in one trip.

In Q1 of 2020 Interra Energy Services had the opportunity to complete a major closable sleeve completion project. The program consisted of 1475 sleeves run in 49 wells with stage counts between 18 and 50 in each well. Interra deployed its Raptor OC® shift-frac-close coil sleeve and Velocity shifting tool. Throughout the project proppant was placed in 100% of the desired intervals and the sleeves were closed with a 99.9% success rate.

In the last two decades there has been a major shift in well design, from vertical to horizontal. With these changes there has been a significant learning curve to optimize well design. In the past, it was standard to leave stage-to-stage spacing at greater lengths up to 300 ft (100 m) with fewer stages per well. With advancements in knowledge and technology, today operators are minimizing stage spacing while maximizing reservoir contact for increased production. As a result, there are thousands of wells previously completed with longer stage spacing that have unstimulated reservoir waiting to be exploited.

On a typical Plug & Perf or Ball Drop completion, it is necessary to establish communication between the toe portion of a horizontal wellbore and the formation. This creates an injection point or a channel to the formation while conveying perforating guns or balls on the first stage of the stimulation process.