Pre-perforated completions are employed in numerous formations in Saskatchewan and Alberta where they provide advantages over conventional plug-and-perf stimulation. Instead of multiple trips in and out of the wellbore to set plugs for stage-to-stage isolation, pre-perforated wells are stimulated using coiled tubing straddle tools, which can treat the entire wellbore in one trip.

Advantages to Running Multiple Howitzer Toe Sleeves Within A Single Wellbore

Challenge

For many Operators, the limiting factor for casing integrity pressure tests is the toe initiation sleeve.

With the depth of high pressure, high temperature (HPHT) well designs, the hydrostatic pressure can limit the maximum applied pressure from surface against the toe initiation sleeves

Solution

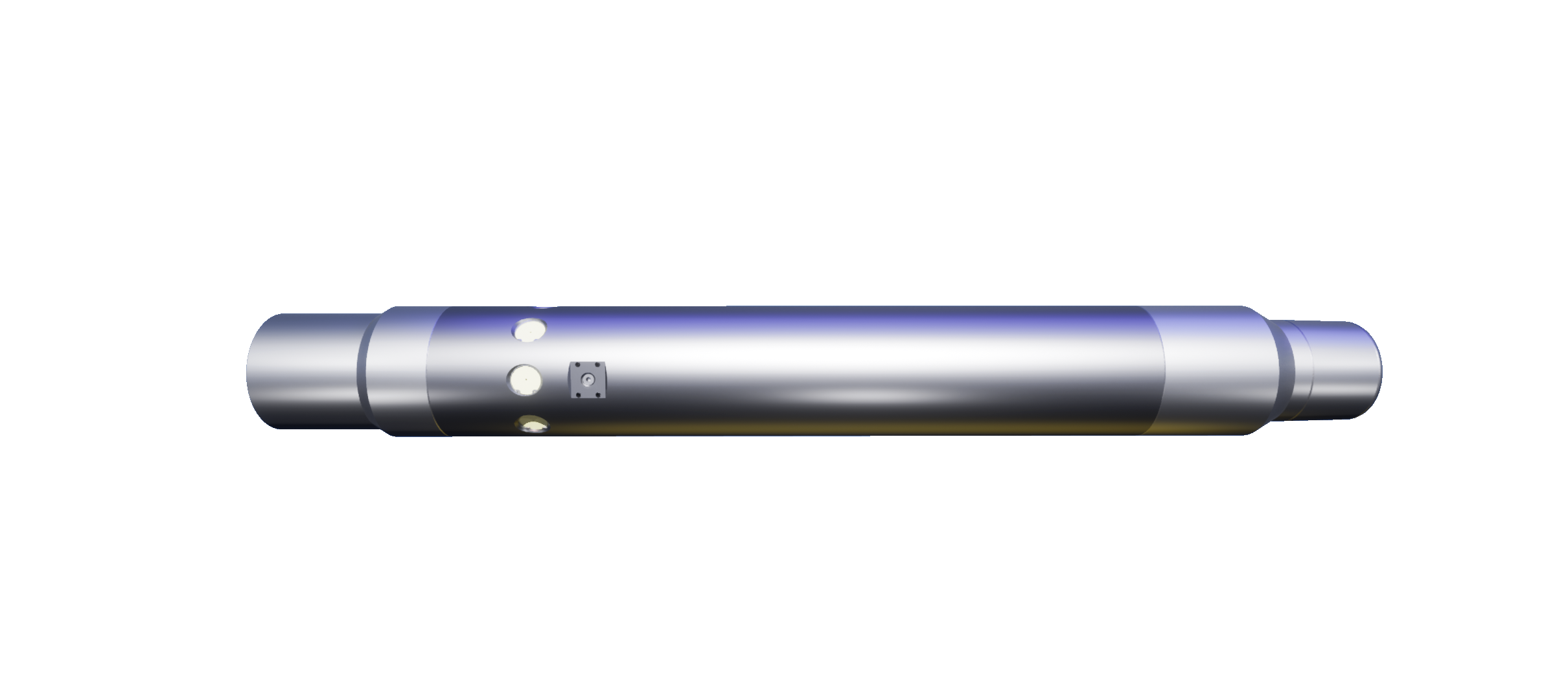

The Howitzer pressure testable toe sleeve design supports higher applied pressure for testing requirements - all ports will independently open on bleed down

Multiple toe ports can be run as a redundancy option

Multiple toe ports in a wellbore reduces the risk of debris (e.g. cement stringers) plugging off the injection ports

Eliminates the need for perforating the first stage of a well

Can be used as the first stimulation stage if desired

Meets all regulatory pressure testing and casing integrity requirements

Results

Running multiple Howitzer toe sleeves is more economical than running other commercial options, and it can also be used as a limited entry frac stage

Savings to customers can exceed greater than $50k per well and 6 – 12 hours of coiled tubing run time

More flow area than competing commercial toe ports

Optional ball seat configuration allows for multiple casing integrity tests

Interra Energy’s Thermal Overshot Resolves Casing Failure in SAGD Environment

Challenge

An operator was experiencing casing failures in SAGD environments and wanted a solution to put their existing wells back on steam injection with minimal intervention required.

Fishing operations to recover the remainder of the string was becoming increasingly expensive due to the casing being structurally compromised in multiple locations and the completion being fished out in pieces.

Solution

Within a 6-week time period, Interra Energy developed the Thermal Overshot allowing operators to re-connect the existing completion string to surface and resume steam injection.

The Thermal Overshot is designed to function without tension or compression, which enables it to maintain a thermal seal for the life of the well.

Through a proprietary slip mechanism, the tool creates a thermal seal around the existing casing, resulting in a continuous flow of steam from surface to the toe of the well.

Results

As of April 2020, Interra Energy has run 10 Thermal Overshot tools with 100% success, all of which are still in operation with the earliest installation being May 2016.

The Thermal Overshot eliminated the risk of costly fishing operations or potentially even losing portions of the well if the completion could not be fished.

Interra Energy Successfully Deploys 16,000 AccuJet® Toe Initiation Sleeves

Challenge

Within the design of conventional burst ports, once one port is activated, pressure can travel outside the port and equalize, preventing other ports from opening.

Solution

Interra Energy challenged itself to create a new toe sleeve that incorporated the proven accuracy of burst discs, while guaranteeing 100% opening of the flow area. This reduced the limitations that were commonly seen with burst ports while injecting into the toe.

Results

The AccuJet toe initiation sleeve design, released by Interra Energy in 2013, uses multiple burst discs that only require one to be activated. This allows a sleeve to shift exposing all of the injection windows to the formation.

As of June 2020, there have been over 16,000 successful deployments of the AccuJet’s technology in such formations as the Viking, Montney, Cardium, Duvernay, Permian, Bakken, Haynesville and the Eagle Ford.

Interra Energy’s Howitzer Pressure Testable Toe Sleeve Enables Casing Integrity Test After Extended Periods Downhole

Challenge

Marcellus Shale frac crew availability results in installations being left downhole over 200 days before successful operation.

Solution

The Howitzer pressure testable toe sleeve was installed in the Marcellus Shale for a major Operator.

Result

After 202 days, the Operator successfully performed a maximum casing pressure test to 12,800 psi for 30 minutes before the Howitzer pressure testable toe sleeve activated and established communication to formation.

1475 Raptor OC® (Open Close) Coil Sleeves Deployed in Q1, 2020

In Q1 of 2020 Interra Energy Services had the opportunity to complete a major closable sleeve completion project. The program consisted of 1475 sleeves run in 49 wells with stage counts between 18 and 50 in each well. Interra deployed its Raptor OC® shift-frac-close coil sleeve and Velocity shifting tool. Throughout the project proppant was placed in 100% of the desired intervals and the sleeves were closed with a 99.9% success rate.

AccuStim® Successfully Restimulates Two Legacy Wells

In the last two decades there has been a major shift in well design, from vertical to horizontal. With these changes there has been a significant learning curve to optimize well design. In the past, it was standard to leave stage-to-stage spacing at greater lengths up to 300 ft (100 m) with fewer stages per well. With advancements in knowledge and technology, today operators are minimizing stage spacing while maximizing reservoir contact for increased production. As a result, there are thousands of wells previously completed with longer stage spacing that have unstimulated reservoir waiting to be exploited.

Crescent Point Energy activates and stimulates a five-stage toe initiation cluster

On a typical Plug & Perf or Ball Drop completion, it is necessary to establish communication between the toe portion of a horizontal wellbore and the formation. This creates an injection point or a channel to the formation while conveying perforating guns or balls on the first stage of the stimulation process.